Modular and Flexible: ZF's EcoMet Sets a New Standard for Metro Gearboxes - Its modular design enables cost-efficient adaptation to customer requirements

- Fast delivery thanks to tried and tested individual components

- Additional digital functions for better condition monitoring

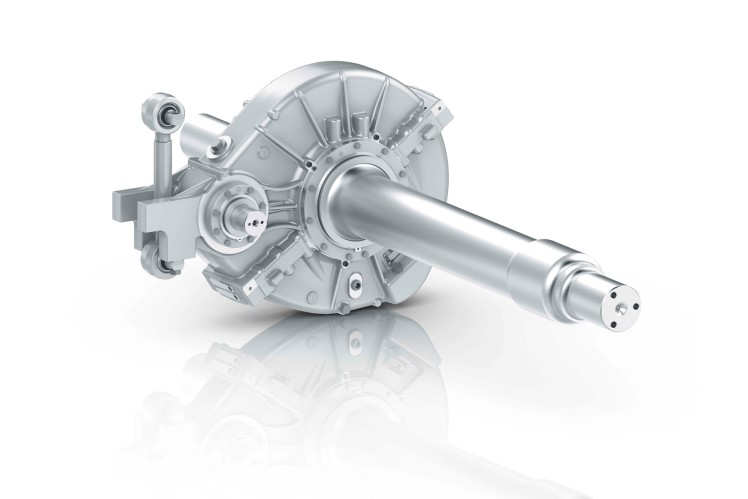

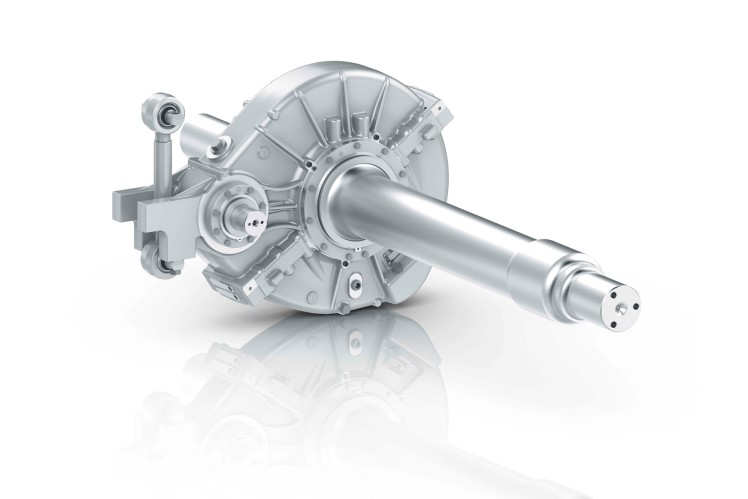

Friedrichshafen/Birmingham. With EcoMet, ZF is setting new standards in performance, flexibility and cost-effectiveness of metro gearboxes. Thanks to its modular design, the gearbox is suitable for a wide variety of metro types, depending on customer requirements, without it being necessary to incur additional development and manufacturing costs. During development, the technology group made good use of its many years of experience as a leading supplier of driveline technology for rail vehicles.

Designing new rail vehicles is usually an expensive task for manufacturers. This is not least due to the fact that uniform standards have not yet been established for the driveline of metros. Every new metro therefore requires engine and gearbox reengineering – including the corresponding effort and costs.

EcoMet, ZF’s new gearbox family, now deals with this challenge flexibly, efficiently and economically. On the basis of a modular construction kit, EcoMet can operate variable center distances (from 350 to 370 mm) and ratios within a single, noise-optimized housing. The gearbox is designed for a maximum axle load of 17 tons and a top speed of 120 km/h at a maximum engine speed of approx. 6,000 rpm. EcoMet thus meets the requirements of all manufacturers who focus on performance and robustness as well as cost-effectiveness. Because ZF uses standardized components of proven quality, the gearbox also leaves the factory with basic protection in terms of oiling, leak tightness, acoustics and load testing. This provides savings on testing and homologation costs for the customer. Thanks to coordinated and streamlined logistics processes, delivery occurs within 8 to 10 months, including appropriate coupling and torque support.

As an additional service available starting in Q3 2019, ZF is planning to provide an online configurator that will allow customers to find out whether EcoMet is suitable for their application quickly and with no obligation.

At a glance: The “connect@rail” condition monitoring system

The comprehensive “connect@rail” condition monitoring system, for which EcoMet is prepared, offers additional added value for manufacturers and operators.

Various sensors record vibrations, oil quality and the temperature behavior of the gearboxes, for example. A platform developed by ZF then reliably transfers the collected data and information to the ZF Cloud. Operators can view the analyses and recommended courses of action based on the above data from the ZF Cloud using a computer or mobile device. Also, they can optimally schedule maintenance dates and respond to the most diverse situations individually and flexibly. This guarantees that the entire fleet is operating smoothly and as cost-efficiently as possible.

- Its modular design enables cost-efficient adaptation to customer requirements

- Fast delivery thanks to tried and tested individual components

- Additional digital functions for better condition monitoring

Friedrichshafen/Birmingham. With EcoMet, ZF is setting new standards in performance, flexibility and cost-effectiveness of metro gearboxes. Thanks to its modular design, the gearbox is suitable for a wide variety of metro types, depending on customer requirements, without it being necessary to incur additional development and manufacturing costs. During development, the technology group made good use of its many years of experience as a leading supplier of driveline technology for rail vehicles.

Designing new rail vehicles is usually an expensive task for manufacturers. This is not least due to the fact that uniform standards have not yet been established for the driveline of metros. Every new metro therefore requires engine and gearbox reengineering – including the corresponding effort and costs.

EcoMet, ZF’s new gearbox family, now deals with this challenge flexibly, efficiently and economically. On the basis of a modular construction kit, EcoMet can operate variable center distances (from 350 to 370 mm) and ratios within a single, noise-optimized housing. The gearbox is designed for a maximum axle load of 17 tons and a top speed of 120 km/h at a maximum engine speed of approx. 6,000 rpm. EcoMet thus meets the requirements of all manufacturers who focus on performance and robustness as well as cost-effectiveness. Because ZF uses standardized components of proven quality, the gearbox also leaves the factory with basic protection in terms of oiling, leak tightness, acoustics and load testing. This provides savings on testing and homologation costs for the customer. Thanks to coordinated and streamlined logistics processes, delivery occurs within 8 to 10 months, including appropriate coupling and torque support.

As an additional service available starting in Q3 2019, ZF is planning to provide an online configurator that will allow customers to find out whether EcoMet is suitable for their application quickly and with no obligation.

At a glance: The “connect@rail” condition monitoring system

The comprehensive “connect@rail” condition monitoring system, for which EcoMet is prepared, offers additional added value for manufacturers and operators.

Various sensors record vibrations, oil quality and the temperature behavior of the gearboxes, for example. A platform developed by ZF then reliably transfers the collected data and information to the ZF Cloud. Operators can view the analyses and recommended courses of action based on the above data from the ZF Cloud using a computer or mobile device. Also, they can optimally schedule maintenance dates and respond to the most diverse situations individually and flexibly. This guarantees that the entire fleet is operating smoothly and as cost-efficiently as possible.

MEDIA

CONTACT

Svenja Mayer