An All-Rounder for All-Wheel Drives: The New Transfer Case TC 27 From ZF - Lighter, faster, more efficient: TC 27 increases payload capacity or reduces fuel consumption

- New suspension method reduces installation cost

- Comprehensive monitoring: Oil sensors help to prevent overload

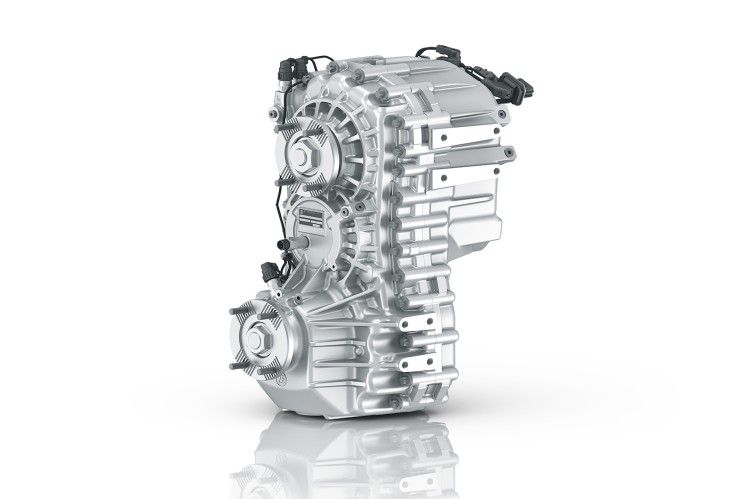

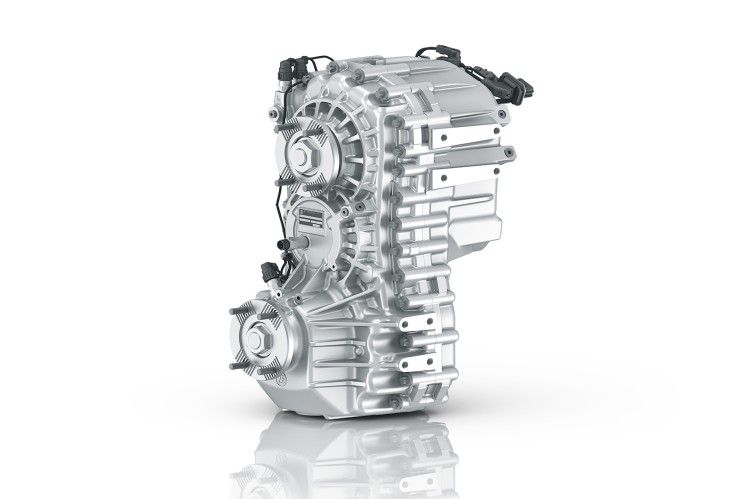

Friedrichshafen/Munich. Once again ZF proves its reputation as being a true driveline specialist for construction equipment: At the Bauma trade fair, the company will introduce its newly developed transfer case TC 27. The TC 27 is designed for demanding all-wheel drive applications. In the new product, ZF unites decades of experience with new benchmarks for efficiency and reliability. Equally, the new transfer case is sleeker, lighter and more flexible in terms of its installation options.

For many years ZF’s transfer case VG 2000 was the benchmark when it came to powerful drive solutions for demanding all-wheel drive applications. In designing the next generation transfer case, ZF took all of the experience obtained with the VG 2000. The TC 27, allows for increased engine output while saving on fuel. It offers a wide variety of configuration options and simplifies installation in the vehicle. The new transfer case is therefore the perfect choice for trucks, all-terrain cranes, dump trucks, articulated haulers and other special AWD vehicles.

Powerful and compact

In comparison to its predecessor, the TC 27 can process a maximum input speed of 3,200 rpm. This enables shorter axle-drive ratios at a constant maximum speed. At a permitted input torque of 27,000 Nm, the transmission is perfectly prepared for demanding all-wheel drive applications. In addition, the power take-off now is now rated to 8,500 Nm. Equally, efficiency has been optimized to such an extent that an external oil cooler is no longer required for many applications. This further simplifies installation saving cost and space. During development of the product, ZF was able to realize further weight optimization – the TC 27 weighs around 100 kg less than its predecessor thanks to its sleeker housing and the use of aluminum. This weight advantage can reduce fuel consumption or increase the load capacity.

Control and overview

Optional sensors which measure the oil level and temperature enable the driver to see the current operating state of the TC 27. Other software functions can be executed via a control unit, if required. The TC 27 can be combined with ZF’s proven Automatic Drivetrain Management (ADM), for example, which controls all inter-axle and inter-wheel differential locks within the vehicle completely automatically. This improves driving stability and at the same time prevents damage to the driveline due to incorrect usage.

Flexible installation

ZF has reduced the number of mounting points to simplify installation of the TC 27. Previously, there were three suspension points, but now there are only two. In addition, thanks to new central connectors, it is now impossible to mix up the pneumatic and electrical connections. Different vehicles provide different installation conditions: The TC 27 comes in two different sizes to respond to this need. The S variant offers 300 mm of shaft distance, while the L variant has a shaft distance of 396 mm. This means that automotive engineers are free to design their drive concepts to best meet their requirements.

- Lighter, faster, more efficient: TC 27 increases payload capacity or reduces fuel consumption

- New suspension method reduces installation cost

- Comprehensive monitoring: Oil sensors help to prevent overload

Friedrichshafen/Munich. Once again ZF proves its reputation as being a true driveline specialist for construction equipment: At the Bauma trade fair, the company will introduce its newly developed transfer case TC 27. The TC 27 is designed for demanding all-wheel drive applications. In the new product, ZF unites decades of experience with new benchmarks for efficiency and reliability. Equally, the new transfer case is sleeker, lighter and more flexible in terms of its installation options.

For many years ZF’s transfer case VG 2000 was the benchmark when it came to powerful drive solutions for demanding all-wheel drive applications. In designing the next generation transfer case, ZF took all of the experience obtained with the VG 2000. The TC 27, allows for increased engine output while saving on fuel. It offers a wide variety of configuration options and simplifies installation in the vehicle. The new transfer case is therefore the perfect choice for trucks, all-terrain cranes, dump trucks, articulated haulers and other special AWD vehicles.

Powerful and compact

In comparison to its predecessor, the TC 27 can process a maximum input speed of 3,200 rpm. This enables shorter axle-drive ratios at a constant maximum speed. At a permitted input torque of 27,000 Nm, the transmission is perfectly prepared for demanding all-wheel drive applications. In addition, the power take-off now is now rated to 8,500 Nm. Equally, efficiency has been optimized to such an extent that an external oil cooler is no longer required for many applications. This further simplifies installation saving cost and space. During development of the product, ZF was able to realize further weight optimization – the TC 27 weighs around 100 kg less than its predecessor thanks to its sleeker housing and the use of aluminum. This weight advantage can reduce fuel consumption or increase the load capacity.

Control and overview

Optional sensors which measure the oil level and temperature enable the driver to see the current operating state of the TC 27. Other software functions can be executed via a control unit, if required. The TC 27 can be combined with ZF’s proven Automatic Drivetrain Management (ADM), for example, which controls all inter-axle and inter-wheel differential locks within the vehicle completely automatically. This improves driving stability and at the same time prevents damage to the driveline due to incorrect usage.

Flexible installation

ZF has reduced the number of mounting points to simplify installation of the TC 27. Previously, there were three suspension points, but now there are only two. In addition, thanks to new central connectors, it is now impossible to mix up the pneumatic and electrical connections. Different vehicles provide different installation conditions: The TC 27 comes in two different sizes to respond to this need. The S variant offers 300 mm of shaft distance, while the L variant has a shaft distance of 396 mm. This means that automotive engineers are free to design their drive concepts to best meet their requirements.

MEDIA

CONTACT

Svenja Mayer