Press Release

ZF’s Global Remanufacturing Initiatives Support Sustainability Commitment

- ZF remanufactures more than 250 different product types for passenger cars, commercial vehicles and off-highway applications

- Over 1,800 global employees are dedicated to remanufacturing in 25 ZF locations worldwide

- Thanks to remanufacturing, ZF can reduce its global C02 emissions by 12,444 tons per year

Today, in recognition of Global Remanufacturing Day, ZF confirmed its continued commitment to remanufacturing and the resulting substantial positive impacts to the environment, economy, and product lifecycles. Remanufacturing enables the Group to significantly reduce CO2 emissions and save energy every year: In 2020 for example, ZF reduced its global CO2 emissions by an estimated 12,444 tons and realized an estimated energy savings of 8,740,000 kWh through remanufacturing - measured against the production of the same quantity of new parts. ZF is offering a steadily growing reman-portfolio of currently 255 product types.

“We all need to be part of the solution when it comes to the sustainability of our planet. Our ambition is to pave the path for a green and sustainable aftermarket. Thanks to our global remanufacturing footprint we are already saving valuable resources today - offering our customers a wide variety of remanufactured products in OEM quality.” said Philippe Colpron, Head of ZF Aftermarket.

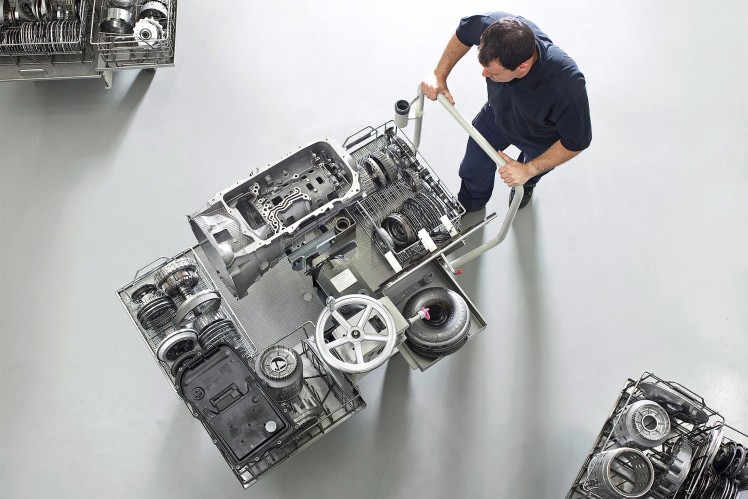

Remanufacturing is the controlled, reproducible, and sustainable industrial process by which previously used products or parts are returned to as-good or better-than-new condition from both a quality and performance perspective. This process enables products to have multiple lifecycles and offers significant time, material, and cost savings when compared to creating a replacement product completely from scratch.

Additionally, as disruptions continue to challenge nearly all industries, remanufacturing fills an increasingly important role in supplying needed parts to help keep supply chains moving.

According to the Remanufacturing Industries Council (RIC), other benefits of remanufacturing include the conservation of raw materials, reduced energy usage, less waste and reduced cost. The remanufacturing process also plays a critical part of the global economy in terms of employment. The council estimates there are nearly a half million global remanufacturing jobs today, employing a wide range of engineers, technicians, scientists, designers and more.

ZF has been involved in the industrial remanufacturing of components and assemblies for vehicles for around 60 years. For remanufacturing the group operates 25 plants and service locations in 15 countries. A total of 1,800 employees at ZF are dedicated to the remanufacturing of products for passenger cars, commercial vehicles and off-highway applications including transmissions, steering systems, axles, torque converters, clutches, brake calipers, engine parts and much more.

“Protecting the environment is one of our main corporate objectives.” said Colpron. “As remanufacturing is an important contributor to circular economy, we are constantly striving to extend our reman capabilities and combining those with other future-facing technologies, such as remanufactured parts for electric vehicles.”

Download Press Information in further languages: