Press Release

ZF Supercharges the Electric Future through Scalable Architectures and Intelligent Software

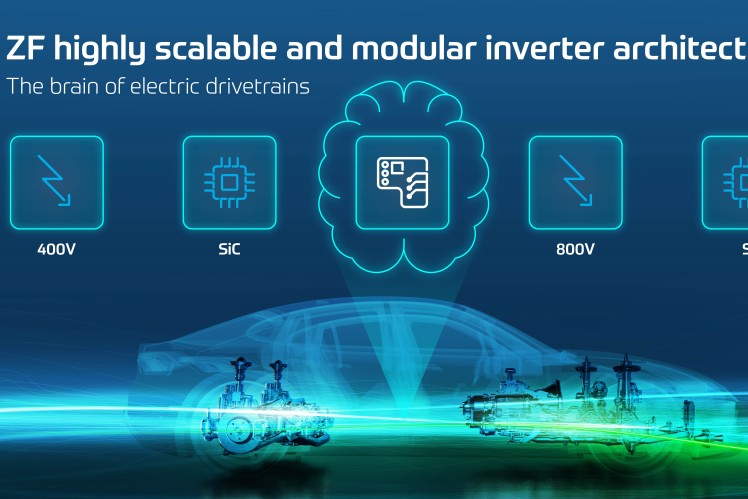

- ZF has developed a scalable and modular e-motor inverter architecture that allows OEMs maximum flexibility from 400V to 800V, from Silicon-to-Silicon Carbide

- Combines advanced inverter design, next generation power semiconductors and highly intelligent software algorithms

- Leverages ZF’s deep experience in electric drives to increase efficiency, peak power and shorten development cycles

The inverter is the brain of electric drivetrains. It manages the flow of energy from battery to e-motor and vice versa. Inverters have become more efficient and more complex with every development step. The next evolution is the combination of the inverter design, next generation power semiconductors and highly intelligent software algorithms.

“The combination of greater scalability and modularity with increased efficiency, peak power and affordability of e-motors is the key to success within the e-mobility market,” said Stephan von Schuckmann, member of the ZF Board of Management and responsible for the Electrified Powertrain Technology division. “The inverter is also where development cycles from the software industry and semiconductor innovations meet automotive hardware and integration expertise. This is where future differentiation will happen.“

Modular and scalable inverter architecture

ZF has developed a highly scalable and modular inverter architecture that allows OEMs maximum flexibility in both 400V and 800V voltage classes.

The modular inverter platform is not dependent on predefined semiconductors and is designed to support vehicle manufacturers in bridging the Silicon-to-Silicon Carbide transition while also being prepared for future semiconductor trends.

ZF semiconductor and software innovation

ZF has been working toward the transition to alternative powertrain technologies for decades and has gained deep knowledge on the inner workings of e-drives, from the holistic design of e-drive systems to software optimization linked to new power semiconductor generations.

Efficiency and peak power of an inverter is not only defined by the properties of the power semiconductors, it is also significantly defined by software. Inverter technology and control software alignment is critical and can be achieved by several feedback loops, in which the inverter hardware provides the software a flow of information (current, temperature, DC-link voltage, etc.) which is used to optimize pulse patterns and switching strategies in real time to improve efficiency and peak power. Especially for Silicon Carbide based systems, ZF has found a solution optimizing the link between the power semiconductor boundary conditions and control software in order to gain the full potential from the semiconductor configuration.

As highlighted earlier the inverter contains the brain controlling the complete e-drive system. As with the human body you can train muscles and the brain to react more efficiently than normally, for example in sports or playing music. This is also what an inverter does - it flexes the e-drive in the most proficient and fastest way.

The control board within an inverter is the home of the inverter software – where the vehicles power demand is translated into the different digital control signals for the driver board that drives the power semiconductors according to the control signals. It is one of the key components of an inverter, because the gate drive technology is responsible for safety features, performance, efficiency and total range of the EV that can be squeezed out of the power semiconductors.

Our new inverter generation brings these hardware and software optimization functionalities to our customers to realize faster power semiconductor switching times, better short circuit protection and much more. ZF has built up significant knowledge in this area both independently and with strong partners such as WOLFSPEED.

Besides a highly scalable approach in terms of voltage and semiconductors, the clever usage of software and semiconductor advancements for inverters are key enablers of the ZF "Modular eDrive Kit" that can reduce the development time for new e-Drives by up to 50 Percent. This world first bundles the entire expertise of ZF's e-mobility team for system solutions, components, and software controls in a flexible and modular platform.

Experts in the path to electrification

“As the industry moves rapidly toward an electrified future and the goals of zero emissions to enhance our environmental future, ZF has the expertise and owns proprietary software and gate drive functions to accelerate the transformation. From significantly faster and safer short circuit protection to gate drivers realizing the absolute maximum performance of power semiconductors, ZF is well-positioned to fulfill the needs of the industry and society,” emphasized von Schuckmann.

These inverter innovations are already being readied for next-generation e-drives that will be ready for production by 2025.