Award-Winning Data Platform from ZF Empowers Efficient Handling of Materials and Goods - deTAGtive enables transparent yard management

- Resource conservation and faster processes

- New hardware tag “deTAGtive call button” completes OPENMATICS asset tracking solution

Friedrichshafen. Smart crosslinking of individual systems via telematics for fleets, logistics processes, goods or company procedures, is a key element in the rapid progress of digitalization. ZF's connectivity solution OPENMATICS not only enables efficient control of materials and goods, but also ensures seamless and networked documentation of transport and logistics processes. This achieves a new dimension of service orientation. With its new hardware tag deTAGtive call button, OPENMATICS rounds off its asset tracking solution, enabling Industry 4.0 on the shop floor as well as in the agile production of the future.

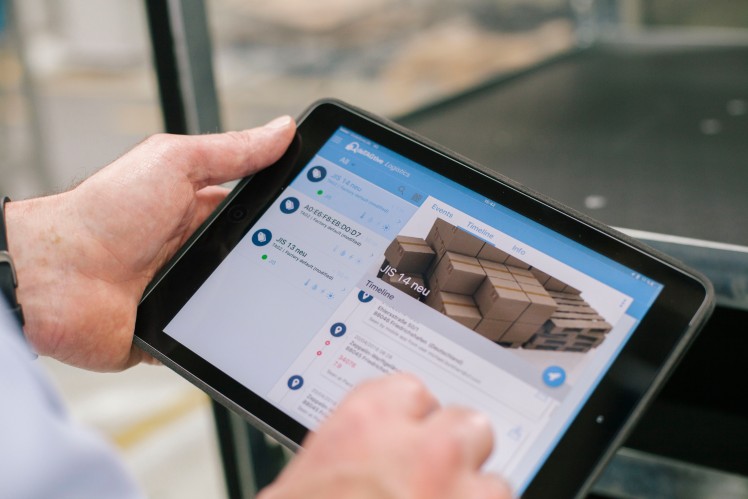

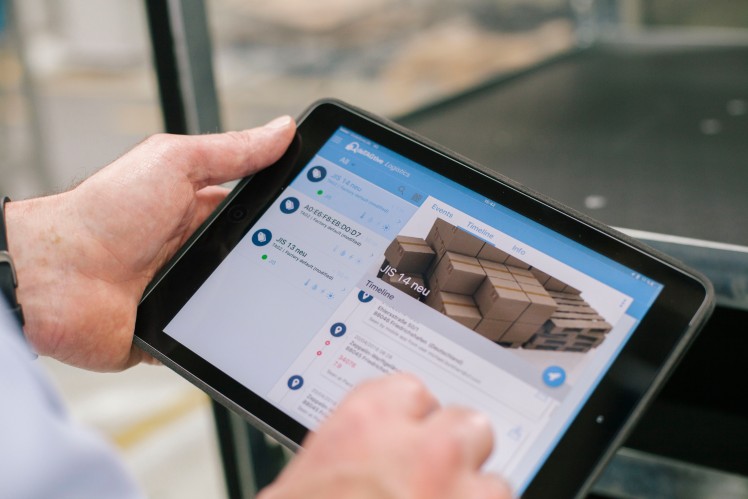

ZF's Cloud Computing platform, based on Microsoft Azure, also plays a key role in the innovative asset tracking solution deTAGtive. At the Zukunftskongress Nutzfahrzeuge (Commercial Vehicle Outlook Congress), this data platform won the 2018 German Telematics Prize. Hardware tags equipped with Bluetooth smart technology manage and monitor the entire material and goods flow on plant yards and depots. Dispatchers can get an overview of transports, vehicles, loading units as well as loading and unloading processes. OPENMATICS thus enables transparent yard management, optimizing work processes while saving time and money.

Pilot project: Dachser takes advantage of the connectivity solution

Logistics service provider Dachser already relies on OPENMATICS’ innovative asset tracking system as part of its yard management. In a pilot project, the company is documenting the entry and exit of swap bodies on the company premises. deTAGtive allows the location of the containers to be recorded accurately and in real time from the external gate to the individual gates of the halls. The automatic identification and localization can not only reduce the time required for handling the containers but also simplify the subsequent internal processes.

“The asset tracking solution in conjunction with Bluetooth Low Energy (BLE) opens up a large number of other application possibilities. Identification and localization of swap bodies is just the beginning,” said Stefan Hohm, head of corporate solutions, research & development at Dachser.

Efficient procurement of materials thanks to deTAGtive call button

With the new hardware tag deTAGtive call button, OPENMATICS completes its asset tracking solution, enabling Industry 4.0 on the shop floor as well as in the agile production of the future, as it is based on autonomous transport units for material which lead directly to the assembly line. The value creation process for logistics can now be controlled completely from a single system. While the previous hardware tags were primarily used to monitor vehicles, goods and transport processes as well as the flow of materials and goods, the deTAGtive call button makes it possible to keep track of material procurement in the production environment, creating an interactive all-in-one intralogistics solution. As soon as material is required, employees on the production line no longer have to use hand-held scanners but can simply place their order at the push of a button directly at their workstations – completely without paper and without much thought or effort.

The call buttons also work via Bluetooth and are compatible with other terminal units and systems and can be used in just-in-time production, where material procurement is carried out in the shortest possible time and as required. By glancing at the LED indicator of the deTAGtive call button, which functions according to the principle of a traffic light, the employee immediately learns the status of their order. Green means that the order is being processed, yellow that the material is ordered and in transit, and red that the order cannot be executed immediately. Thomas Rösch, general manager of OPENMATICS, explains the advantages of the deTAGtive call buttons: “Industry 4.0 requires intelligent networking of production and material procurement – in a manner that is digital, fast and flexible. The deTAGtive call button provides the right solution. Thanks to its easy installation and flexible application, it enables demand-oriented material procurement at the touch of a button and can be used in many ways in production as well as in production logistics.”

- deTAGtive enables transparent yard management

- Resource conservation and faster processes

- New hardware tag “deTAGtive call button” completes OPENMATICS asset tracking solution

Friedrichshafen. Smart crosslinking of individual systems via telematics for fleets, logistics processes, goods or company procedures, is a key element in the rapid progress of digitalization. ZF's connectivity solution OPENMATICS not only enables efficient control of materials and goods, but also ensures seamless and networked documentation of transport and logistics processes. This achieves a new dimension of service orientation. With its new hardware tag deTAGtive call button, OPENMATICS rounds off its asset tracking solution, enabling Industry 4.0 on the shop floor as well as in the agile production of the future.

ZF's Cloud Computing platform, based on Microsoft Azure, also plays a key role in the innovative asset tracking solution deTAGtive. At the Zukunftskongress Nutzfahrzeuge (Commercial Vehicle Outlook Congress), this data platform won the 2018 German Telematics Prize. Hardware tags equipped with Bluetooth smart technology manage and monitor the entire material and goods flow on plant yards and depots. Dispatchers can get an overview of transports, vehicles, loading units as well as loading and unloading processes. OPENMATICS thus enables transparent yard management, optimizing work processes while saving time and money.

Pilot project: Dachser takes advantage of the connectivity solution

Logistics service provider Dachser already relies on OPENMATICS’ innovative asset tracking system as part of its yard management. In a pilot project, the company is documenting the entry and exit of swap bodies on the company premises. deTAGtive allows the location of the containers to be recorded accurately and in real time from the external gate to the individual gates of the halls. The automatic identification and localization can not only reduce the time required for handling the containers but also simplify the subsequent internal processes.

“The asset tracking solution in conjunction with Bluetooth Low Energy (BLE) opens up a large number of other application possibilities. Identification and localization of swap bodies is just the beginning,” said Stefan Hohm, head of corporate solutions, research & development at Dachser.

Efficient procurement of materials thanks to deTAGtive call button

With the new hardware tag deTAGtive call button, OPENMATICS completes its asset tracking solution, enabling Industry 4.0 on the shop floor as well as in the agile production of the future, as it is based on autonomous transport units for material which lead directly to the assembly line. The value creation process for logistics can now be controlled completely from a single system. While the previous hardware tags were primarily used to monitor vehicles, goods and transport processes as well as the flow of materials and goods, the deTAGtive call button makes it possible to keep track of material procurement in the production environment, creating an interactive all-in-one intralogistics solution. As soon as material is required, employees on the production line no longer have to use hand-held scanners but can simply place their order at the push of a button directly at their workstations – completely without paper and without much thought or effort.

The call buttons also work via Bluetooth and are compatible with other terminal units and systems and can be used in just-in-time production, where material procurement is carried out in the shortest possible time and as required. By glancing at the LED indicator of the deTAGtive call button, which functions according to the principle of a traffic light, the employee immediately learns the status of their order. Green means that the order is being processed, yellow that the material is ordered and in transit, and red that the order cannot be executed immediately. Thomas Rösch, general manager of OPENMATICS, explains the advantages of the deTAGtive call buttons: “Industry 4.0 requires intelligent networking of production and material procurement – in a manner that is digital, fast and flexible. The deTAGtive call button provides the right solution. Thanks to its easy installation and flexible application, it enables demand-oriented material procurement at the touch of a button and can be used in many ways in production as well as in production logistics.”

MEDIA

CONTACT