Intelligent Gearbox Systems for More Efficiency and Reliability in Track-borne Vehicles - Contribution to the reduction of operating costs of the total rail system, to performance optimization and to increasing reliability

- Latest sensors and data analysis tools applied profitably in rail applications

- Integrated sensors and the associated data analysis highlight the path to the "Smart Gearbox" of the future

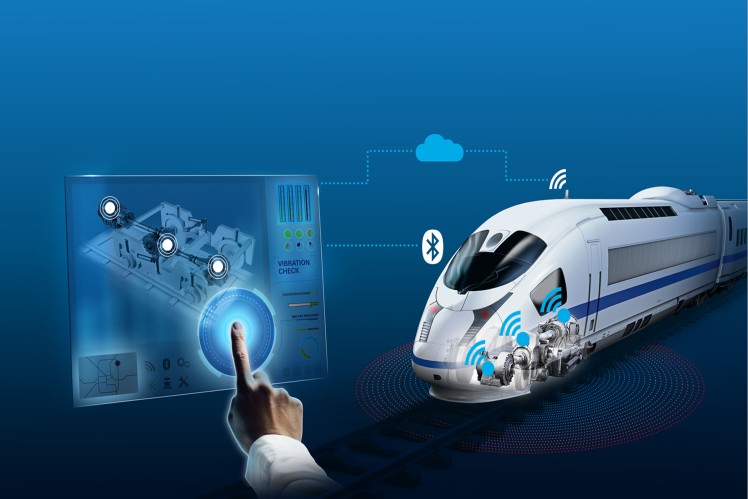

Digitalization has long ago reached the rail industry: The demand for monitoring systems with permanent data connection and automatic evaluation is rising. This requires new concepts. With its intelligent gearbox system, ZF has developed solutions for precisely these demands. It contributes to an optimum use of data about gearbox conditions and infrastructure. Thus, on-demand maintenance can be initiated.

With the intelligent gearbox concept for track-borne transport ZF presents a range of innovative approaches and shows how the latest sensors and data analysis tools can be used profitably for rail applications. The intelligent gearbox boosts the efficiency and reliability of track-borne vehicles and infrastructure. Thus, ZF makes an important contribution to the reduction of operating costs of the total rail system, to performance optimization and to increasing reliability

A pilot project, in which a gearbox has been installed in a tram, has been started. The focus is placed on detecting the condition of the track, the switch stand and components in the train, such as axles and bearings. Evaluation and documentation are put to the test.

The intelligent gearbox concept from ZF offers the following functions:

Vibration Monitoring

Integrated sensors produce data records. In combination with appropriate data analysis tools those data facilitate remote monitoring or analysis of the gearbox functions and condition as well as early detection of potential fault sources. Amongst others, the system monitors and analyses the condition of the bearings, gear teeth and housing.

The system functions are supplemented by external information and ambient parameters. Through this data the operator can react individually and flexibly to the most varied situations and ambient influences. Thus, the goal concerning optimum availability of the fleet of track-borne vehicles is actively supported.

Determination of the oil condition and the temperature behavior

The installed technology enables the most varied oil parameters to be monitored and specifically linked to the current temperature behavior of roller bearings and gearbox oil. The current information from all installed sensors can be relayed via the mobile phone network or various data transfer stations along the route almost in real time. The data can also be retrieved in the batch mode. The operating company therefore always has complete transparency with up-to-date data evaluation. It can therefore carry out efficient vehicle checks as well as early detection of failures. Consequently, trouble-free and cost-optimized operation of a fleet of track-borne vehicles is possible with reduced maintenance.

Smart Typeplate – the ID card for the gearbox

The ZF Smart Typeplate opens up great potential. The original type-plate is provided with an integrated chip. Information is stored locally or in a cloud and is available at any time. Read-out takes place with existing devices, such as smartphones. With the Smart Typeplate, operating hours can be monitors, which enable documentation of each part of the driveline. Via networking, the component’s product data can be automatically displayed.

The technologies, which have been applied in ZFs intelligent gearbox system, bear a huge potential for the industry. ZF has recognized the trend towards monitoring of transmission data timely and places more emphasis on research and development of the Internet of Things.

- Contribution to the reduction of operating costs of the total rail system, to performance optimization and to increasing reliability

- Latest sensors and data analysis tools applied profitably in rail applications

- Integrated sensors and the associated data analysis highlight the path to the "Smart Gearbox" of the future

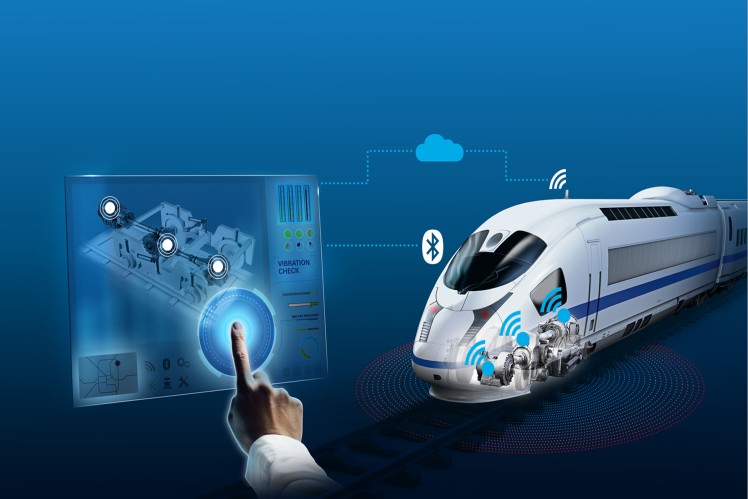

Digitalization has long ago reached the rail industry: The demand for monitoring systems with permanent data connection and automatic evaluation is rising. This requires new concepts. With its intelligent gearbox system, ZF has developed solutions for precisely these demands. It contributes to an optimum use of data about gearbox conditions and infrastructure. Thus, on-demand maintenance can be initiated.

With the intelligent gearbox concept for track-borne transport ZF presents a range of innovative approaches and shows how the latest sensors and data analysis tools can be used profitably for rail applications. The intelligent gearbox boosts the efficiency and reliability of track-borne vehicles and infrastructure. Thus, ZF makes an important contribution to the reduction of operating costs of the total rail system, to performance optimization and to increasing reliability

A pilot project, in which a gearbox has been installed in a tram, has been started. The focus is placed on detecting the condition of the track, the switch stand and components in the train, such as axles and bearings. Evaluation and documentation are put to the test.

The intelligent gearbox concept from ZF offers the following functions:

Vibration Monitoring

Integrated sensors produce data records. In combination with appropriate data analysis tools those data facilitate remote monitoring or analysis of the gearbox functions and condition as well as early detection of potential fault sources. Amongst others, the system monitors and analyses the condition of the bearings, gear teeth and housing.

The system functions are supplemented by external information and ambient parameters. Through this data the operator can react individually and flexibly to the most varied situations and ambient influences. Thus, the goal concerning optimum availability of the fleet of track-borne vehicles is actively supported.

Determination of the oil condition and the temperature behavior

The installed technology enables the most varied oil parameters to be monitored and specifically linked to the current temperature behavior of roller bearings and gearbox oil. The current information from all installed sensors can be relayed via the mobile phone network or various data transfer stations along the route almost in real time. The data can also be retrieved in the batch mode. The operating company therefore always has complete transparency with up-to-date data evaluation. It can therefore carry out efficient vehicle checks as well as early detection of failures. Consequently, trouble-free and cost-optimized operation of a fleet of track-borne vehicles is possible with reduced maintenance.

Smart Typeplate – the ID card for the gearbox

The ZF Smart Typeplate opens up great potential. The original type-plate is provided with an integrated chip. Information is stored locally or in a cloud and is available at any time. Read-out takes place with existing devices, such as smartphones. With the Smart Typeplate, operating hours can be monitors, which enable documentation of each part of the driveline. Via networking, the component’s product data can be automatically displayed.

The technologies, which have been applied in ZFs intelligent gearbox system, bear a huge potential for the industry. ZF has recognized the trend towards monitoring of transmission data timely and places more emphasis on research and development of the Internet of Things.

MEDIA

CONTACT