Cloud-based Solution Reduces Costs for Wind Park Operators - New cloud-based service makes wind turbines more reliable and more efficient

- Cloud-based solution reduces OPEX for wind turbines

- Monitoring of entire drivetrain during operation

At Hanover Trade Fair 2018, ZF Friedrichshafen AG presents digital solutions for wind power. A new, cloud-based platform improves the monitoring options for wind turbine gearboxes and components, reduces the costs for wind farm operators and enables advanced functions like predicitive maintenance.

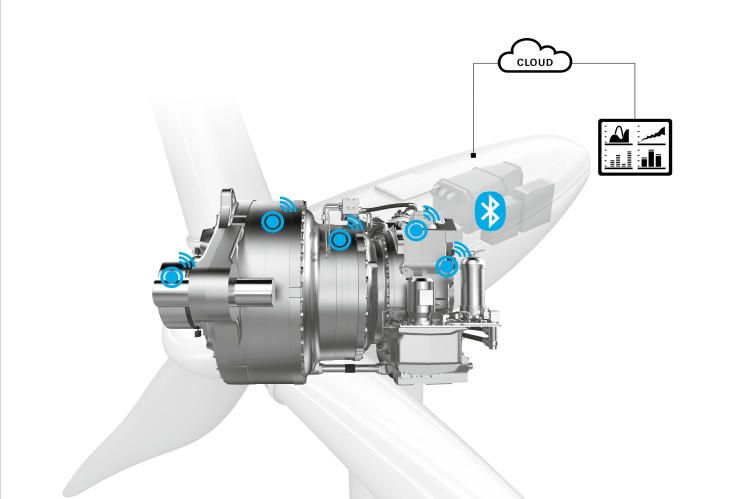

The ongoing digitalization also affects the wind industry and transforms the way wind turbines will be operated and maintained in the future. ZF’s Intelligent Gearbox in connection with the new cloud platform responds to the demand for intelligent wind turbine performance management.

A cloud-based solution with the focus on drivetrain performance

The system monitors the complete drivetrain of the wind turbine during operation. The the data gathered are used to produce a ‚virtual twin` of the real gearbox. The performance and condition of the wind turbine can be monitored and predicted remotely using this.

“With our cloud-based solution, we constantly improve the reliability of the drivetrains of wind turbines. Furthermore, operators can assess data concerning performance in real-time and plan maintenance work predictively”, explains Dr. Klaus Geißdörfer, Head of ZF’s Division Industrial Technology.

Also, thanks to the new, cloud-based solution, connected gearboxes can automatically calculate the best way to operate. At any time this optimizes energy generation under any weather condition. Overloading of the gearbox is prevented to as great an extent as possible.

Furthermore, the solution enables advanced and optimized planning of maintenance work and a constant improvement of the coordination of the current capacity of the gearbox. This leads to an increase in efficiency as well as to a minimization of downtimes, thus decreasing operational costs for both manufacturers and operators. This ultimately results in lower generation costs for wind energy.

Unique collaborative approach

“In order to make wind gearboxes technically future-proof, new gearbox functions and services must be based around a new digital platform which can be used by many users”, explains Jan Willem Ruinemans, Head of ZF’s Wind Power Technology Business Unit.

For this, ZF offers the optimal basis, as standards in the construction of connected gearboxes and strategies in operational control have already been established. Thanks to standardized interfaces and encrypted communication via Internet or VPN connections, the cloud-based platform has standardized interfaces etc., which enable open cloud-to-cloud solutions. This facilitates the monitoring of wind parks on a global scale as well as providing the option to collaborate with partners.

- New cloud-based service makes wind turbines more reliable and more efficient

- Cloud-based solution reduces OPEX for wind turbines

- Monitoring of entire drivetrain during operation

At Hanover Trade Fair 2018, ZF Friedrichshafen AG presents digital solutions for wind power. A new, cloud-based platform improves the monitoring options for wind turbine gearboxes and components, reduces the costs for wind farm operators and enables advanced functions like predicitive maintenance.

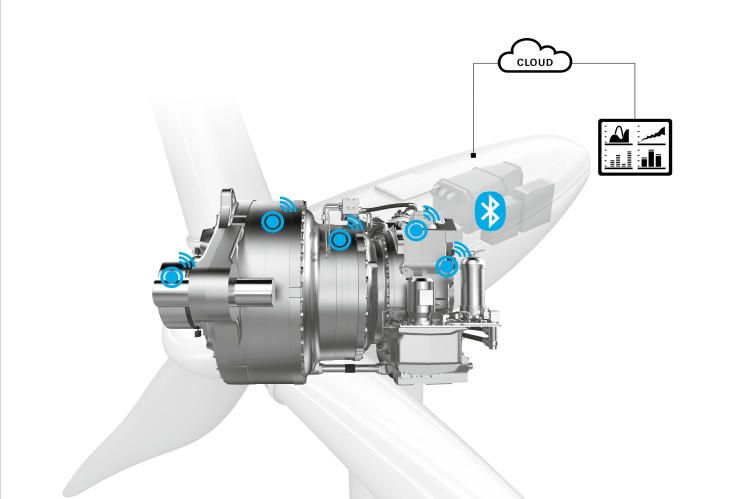

The ongoing digitalization also affects the wind industry and transforms the way wind turbines will be operated and maintained in the future. ZF’s Intelligent Gearbox in connection with the new cloud platform responds to the demand for intelligent wind turbine performance management.

A cloud-based solution with the focus on drivetrain performance

The system monitors the complete drivetrain of the wind turbine during operation. The the data gathered are used to produce a ‚virtual twin` of the real gearbox. The performance and condition of the wind turbine can be monitored and predicted remotely using this.

“With our cloud-based solution, we constantly improve the reliability of the drivetrains of wind turbines. Furthermore, operators can assess data concerning performance in real-time and plan maintenance work predictively”, explains Dr. Klaus Geißdörfer, Head of ZF’s Division Industrial Technology.

Also, thanks to the new, cloud-based solution, connected gearboxes can automatically calculate the best way to operate. At any time this optimizes energy generation under any weather condition. Overloading of the gearbox is prevented to as great an extent as possible.

Furthermore, the solution enables advanced and optimized planning of maintenance work and a constant improvement of the coordination of the current capacity of the gearbox. This leads to an increase in efficiency as well as to a minimization of downtimes, thus decreasing operational costs for both manufacturers and operators. This ultimately results in lower generation costs for wind energy.

Unique collaborative approach

“In order to make wind gearboxes technically future-proof, new gearbox functions and services must be based around a new digital platform which can be used by many users”, explains Jan Willem Ruinemans, Head of ZF’s Wind Power Technology Business Unit.

For this, ZF offers the optimal basis, as standards in the construction of connected gearboxes and strategies in operational control have already been established. Thanks to standardized interfaces and encrypted communication via Internet or VPN connections, the cloud-based platform has standardized interfaces etc., which enable open cloud-to-cloud solutions. This facilitates the monitoring of wind parks on a global scale as well as providing the option to collaborate with partners.