“ZF Innovation Forklift” – an Electric Forklift Able to See, Think and Act - ZF develops intelligent mechanical systems for electric forklifts

- Focus on safety: surround view and object recognition

- Driveline systems from ZF create a foundation for autonomous driving

In this era, where purchases are made via the internet and manufacturing has to be just-in-time, are just a few of the challenges that the logistics industry has to face: goods have to be transported quickly, efficiently and without damage while the risks for employees are minimized. Vehicles of the future must therefore be able to transport goods in a safe and energy-efficient manner, thus supporting the driver as much as possible in their day-to-day-work. With the Innovation Forklift, which is introduced at the Hannover Messe trade fair, ZF offers a solution which deals to these challenges.

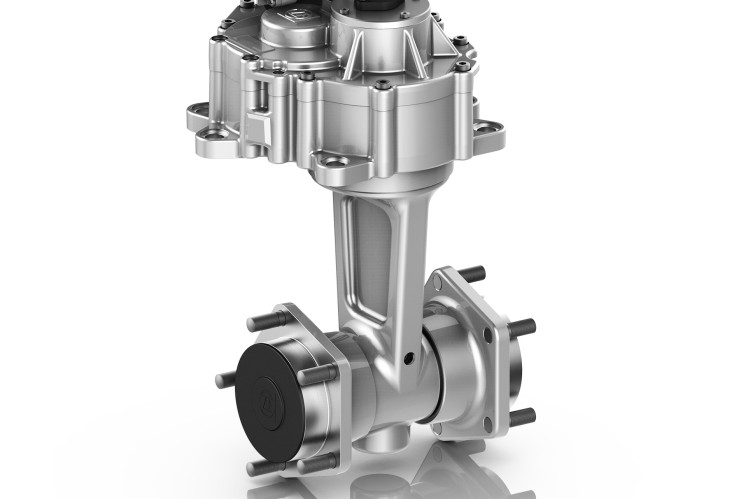

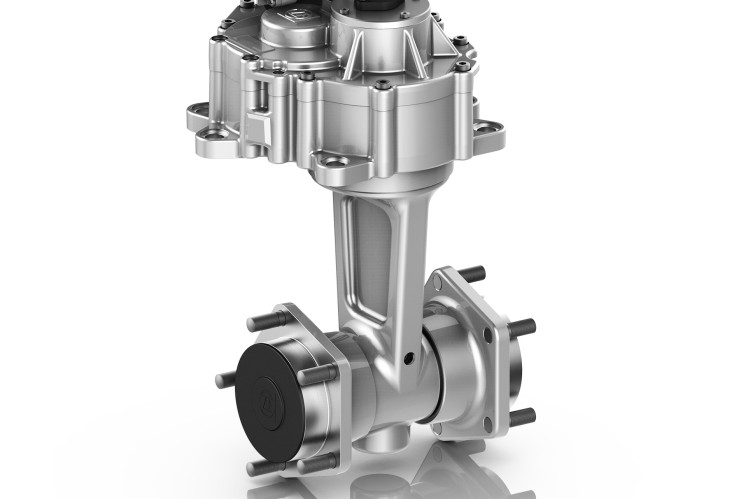

What are the novel features of this forklift? Existing electric driveline components have been extended and now include environmental sensors such as radar and camera systems. This technology supports drivers through rear-view monitoring for the vehicle and warns them of obstructions or pedestrians in the danger zone and also provides local navigation from the interior. Automated operations are enabled by driveline elements, such as the electromechanical power steering ZF eSTEER EPS 3, which replaces the hydrostatic steering used to date and also reduces energy consumption by more than 10 percent, as well as the twin-engine series eTRAC GP 25 (image 3).

ZF Automated operations

Developing the ZF Innovation Forklift would have been impossible without the ZF ProAI processor (image 1). ZF ProAI allows vehicles to 'understand' their environment by processing and interpreting it using sensor data with deep learning technology. The two companies are also developing solutions for highly and completely automated driving and working, including driving features for passenger and commercial vehicles and applications in the field of industrial technology. ZF and its partners have used cameras, lasers and radar sensors to develop sub-systems for highly automated functions in off-highway applications.

Automated driving

Safety, relieving the driver of work and process automation are becoming increasingly important in the logistics industry. ZF has headed this trend and developed an Innovation Forklift with highly automated driving functions (image 2). Currently, the technology is undergoing an extensive program of tests with the aim of taking it into volume production.

"The test vehicle demonstrates how material handling can also benefit from megatrends such as connectivity and artificial intelligence," says Dr Mark Mohr, Head of the Automated Operations project team at ZF, commenting on the ground-breaking innovation which ZF has equipped with a range of intelligent systems. Vehicles are fitted with an array of cameras and radar sensors providing them with a surround-view system capable of person and object recognition. Its signals are processed by ZF ProAI, a high- performance electronic system capable of deep learning. "Used in conjunction with our steering and transmission systems developed in-house automated process flows in warehouse logistics are now a possibility," explains Dr Mark Mohr.

Safety is endured by surround view and object recognition

Automated driving requires an exceptional level of safety, which is guaranteed by the Innovation Forklift. "The vehicle is capable of surround view and pedestrian and object recognition, thanks to its built-in ZF cameras. Wherever possible, it brings the vehicle to an immediate stop if pedestrians suddenly appear and also enables it to go around static objects", states Dr Mohr.

Laying the foundations for automated operations: ZF Driveline technology

The automated driving functions mentioned above are enabled by the electric driveline components, which ZF has been offering for years. ZF has further improved its twin-engine drive series eTRAC GP 25 for this purpose. Today, such motors are setting efficiency benchmarks for energy efficiency and noise pollution, which has been confirmed in tests carried out by independent trade publications. Anyone who uses this forklift will appreciate its long maintenance cycles.The electromechanical power steering system eSTEER EPS3 (image 4) replaces the hydrostatic steering used up until now in three-wheel front-drive counterbalance forklifts up to 2 tons.

The main benefits include:

- Save over 10% energy in the driving cycle

- Reduced energy consumption / longer battery life through power on demand

- Easier installation during forklift assembly

- An ideal complement to the GP 25

- Front drive ensures optimum maneuverability and energy efficiency

- Noise is reduced through perfect gearing design

- ZF develops intelligent mechanical systems for electric forklifts

- Focus on safety: surround view and object recognition

- Driveline systems from ZF create a foundation for autonomous driving

In this era, where purchases are made via the internet and manufacturing has to be just-in-time, are just a few of the challenges that the logistics industry has to face: goods have to be transported quickly, efficiently and without damage while the risks for employees are minimized. Vehicles of the future must therefore be able to transport goods in a safe and energy-efficient manner, thus supporting the driver as much as possible in their day-to-day-work. With the Innovation Forklift, which is introduced at the Hannover Messe trade fair, ZF offers a solution which deals to these challenges.

What are the novel features of this forklift? Existing electric driveline components have been extended and now include environmental sensors such as radar and camera systems. This technology supports drivers through rear-view monitoring for the vehicle and warns them of obstructions or pedestrians in the danger zone and also provides local navigation from the interior. Automated operations are enabled by driveline elements, such as the electromechanical power steering ZF eSTEER EPS 3, which replaces the hydrostatic steering used to date and also reduces energy consumption by more than 10 percent, as well as the twin-engine series eTRAC GP 25 (image 3).

ZF Automated operations

Developing the ZF Innovation Forklift would have been impossible without the ZF ProAI processor (image 1). ZF ProAI allows vehicles to 'understand' their environment by processing and interpreting it using sensor data with deep learning technology. The two companies are also developing solutions for highly and completely automated driving and working, including driving features for passenger and commercial vehicles and applications in the field of industrial technology. ZF and its partners have used cameras, lasers and radar sensors to develop sub-systems for highly automated functions in off-highway applications.

Automated driving

Safety, relieving the driver of work and process automation are becoming increasingly important in the logistics industry. ZF has headed this trend and developed an Innovation Forklift with highly automated driving functions (image 2). Currently, the technology is undergoing an extensive program of tests with the aim of taking it into volume production.

"The test vehicle demonstrates how material handling can also benefit from megatrends such as connectivity and artificial intelligence," says Dr Mark Mohr, Head of the Automated Operations project team at ZF, commenting on the ground-breaking innovation which ZF has equipped with a range of intelligent systems. Vehicles are fitted with an array of cameras and radar sensors providing them with a surround-view system capable of person and object recognition. Its signals are processed by ZF ProAI, a high- performance electronic system capable of deep learning. "Used in conjunction with our steering and transmission systems developed in-house automated process flows in warehouse logistics are now a possibility," explains Dr Mark Mohr.

Safety is endured by surround view and object recognition

Automated driving requires an exceptional level of safety, which is guaranteed by the Innovation Forklift. "The vehicle is capable of surround view and pedestrian and object recognition, thanks to its built-in ZF cameras. Wherever possible, it brings the vehicle to an immediate stop if pedestrians suddenly appear and also enables it to go around static objects", states Dr Mohr.

Laying the foundations for automated operations: ZF Driveline technology

The automated driving functions mentioned above are enabled by the electric driveline components, which ZF has been offering for years. ZF has further improved its twin-engine drive series eTRAC GP 25 for this purpose. Today, such motors are setting efficiency benchmarks for energy efficiency and noise pollution, which has been confirmed in tests carried out by independent trade publications. Anyone who uses this forklift will appreciate its long maintenance cycles.The electromechanical power steering system eSTEER EPS3 (image 4) replaces the hydrostatic steering used up until now in three-wheel front-drive counterbalance forklifts up to 2 tons.

The main benefits include:

- Save over 10% energy in the driving cycle

- Reduced energy consumption / longer battery life through power on demand

- Easier installation during forklift assembly

- An ideal complement to the GP 25

- Front drive ensures optimum maneuverability and energy efficiency

- Noise is reduced through perfect gearing design

MEDIA

CONTACT

Lukas Hildebrand