Press Release

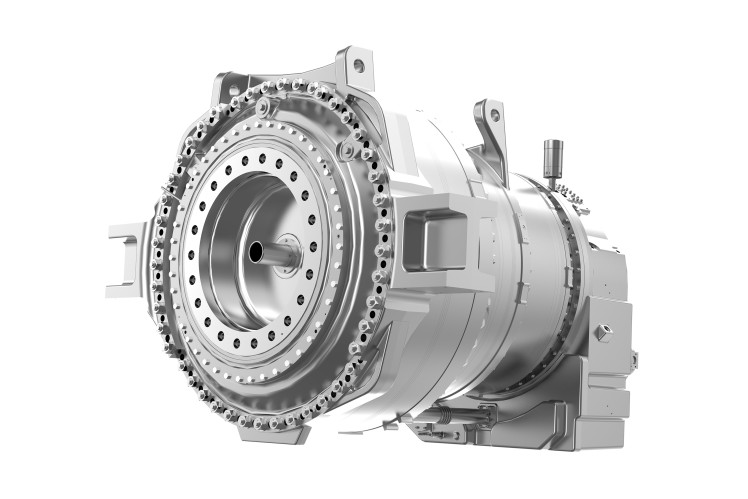

ZF Wind Power breaks 200 Nm/kg torque density barrier with the modular gearbox platform SHIFT 7k

- SHIFT, ZF’s modular gearbox platform, has been extended with two new members - SHIFT 3k to the lower end of the torque scale and SHIFT 7k at the high end.

- Together with the 4k and 6k variants, the SHIFT platform family enables cost-efficient turbine designs for all markets with wind power densities starting from 125 W/m2 up to 500 W/m2.

- Thanks to the implementation of several new technologies, ZF was able to cross the 200 Nm/kg barrier with the new SHIFT 7k platform.

Lommel, Belgium. ZF Wind Power extends its modular gearbox platform, SHIFT, with two new members: SHIFT 3k and SHIFT 7k.

Where the SHIFT 7k variant with a torque range up to 8000kNm addresses the high power, high output onshore segments as well as dedicated offshore markets, the SHIFT 3k variant covers the requirements for high capacity factors in low to very low wind sites to boost annual energy production. Together with SHIFT 4k and SHIFT 6k, the SHIFT platform is now able to maximize energy production at every wind site.

With a torque range covering 3000 to 8000 kNm, ZF Wind Power’s SHIFT modular gearbox platform portfolio enables cost-efficient turbine designs for all markets with a wind power density ranging from 125 W/m2 up to 500 W/m2.

In terms of torque density, the 3k and 7k designs in the SHIFT product family clearly raise the bar in their respective segments, with the SHIFT 7k even surpassing the 200 Nm/kg mark. This industry leading torque density allows for lightweight platform gearboxes able to cope with a broad range of high torques, reducing the levelized cost of energy for wind power. Higher torque density means less material is needed to handle torque. Compact and lightweight gearbox designs play an increasingly important role in reducing nacelle weights as turbine tower heights continue to grow to boost customers’ annual energy production.

This important step-up in torque density has been made possible by ZF’s long term fundamental R&D to continuously advancing state-of-the-art gearbox design, components and materials. To achieve an overall ratio of 200, the SHIFT 7k variant has been designed with four stages in total, of which the first two have a higher number of planets in comparison with its 4k and 6k counterparts. “Optimization of load sharing in these multi-planet stages is the ‘fine art’ of gearbox design combined with selective assembly of components in the assembly process,” explains Martin Knops, CTO of ZF Wind Power.”

During its 40 years of activity in the wind market, ZF Wind Power has shipped 150 GW of high-end gearboxes worldwide, of which 75% of today’s shipments is based on the SHIFT modular platform design. SHIFT is a highly scalable platform, enabling new innovative turbine designs for the energy supply of the future. The platform approach has been already proven in the automotive industry, but is still quite new to the wind turbine gearbox market. The SHIFT platform uses standardized building blocks to offer maximum flexibility to wind turbine manufacturers. It offers the opportunity to quickly introduce new turbine models which enable the customers’ levelized cost of energy reduction through a shorter time to market. In addition, the modular platform approach allows a further optimization of gearbox configurations per wind site and lowers the total investment and development cost.

“The introduction of the SHIFT gearbox platform family, four years ago, clearly marked a leap in gearbox development strategy in tune with market needs. With the introduction of the SHIFT 3k and SHIFT 7k, the modular gearbox platform is synchronized with evolving wind turbine platform requirements. In doing so, ZF Wind Power delivers on its commitment to make wind energy one of the most cost-efficient renewable energy sources powering the global energy shift, “says Hans Akkermans, CCO of ZF Wind Power.

Visit our SHIFTx launch platform to discover the complete modular gearbox platform and the technology that helped us cross the 200 Nm/kg barrier: www.shifttowardsthefuture.com

Please download our SHIFT leaflet "SHIFT modular gearbox platforms enable maximization of energy output at every wind site" here.