Cabin suspension and damping technology from ZF – The optimized solution for every application - Customized designs meet all customer requirements

- ZF products increase driving safety and comfort

Top working conditions in the cabin are becoming increasingly important for the success of construction vehicles. With its spring/damper units and systems, ZF is offering the ideal solution for almost any application, covering the whole range from steel spring module and air spring module to Cabin Air Levelling Module CALM and eCALM with integrated levelling control.

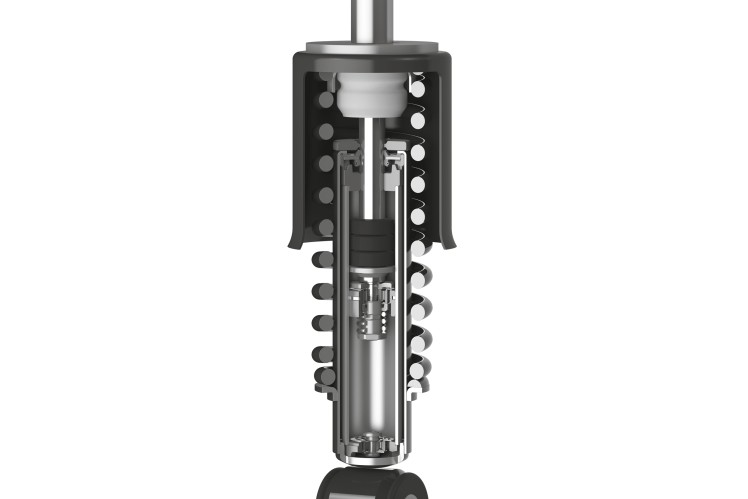

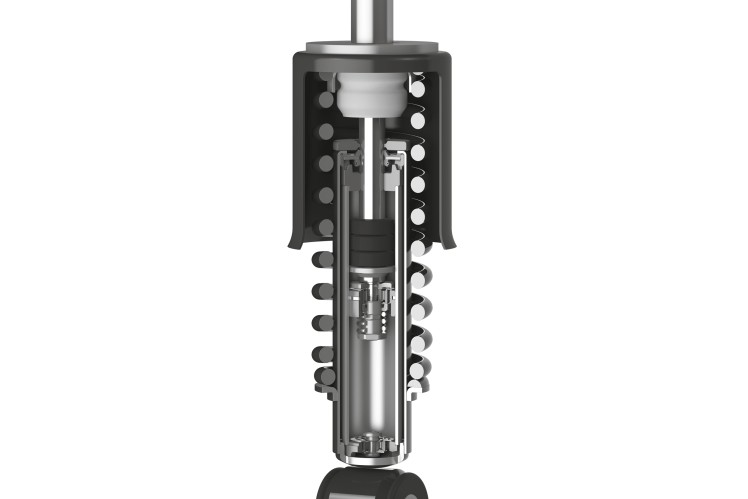

The steel-spring module (fig. 17) is the standard solution for cabins in construction machines and special-purpose vehicles. The advantages of steel springs in cabin dampers include simple installation by vehicle manufacturers, compact dimensions, and operations that do not require pressurized air.

Air springs for higher demands

The air-spring module provides considerably greater comfort. It is especially suited for installation in vehicles that carry a wide range of different loads – including in the cabin itself. It compensates for different cabin furnishings and ensures very comfortable damping and suspension performance.

CALM: Cabin Air Levelling Module

A further development of the air-spring module is the Cabin Air Levelling Module (CALM), which ZF developed together with WABCO. This module contains an integrated ride-height control system for the cabin. Depending on cabin height, a valve regulates the pressure in the air spring. CALM offers all the advantages of air springs, and in addition, its integrated height-control valve reduces the dimensions and simplifies installation. This additionally increases the reliability of the ride-height control system and prevents a dirt-related failure of the control valve.

eCALM: electronically controlled height leveling

The ongoing further development of the successful CALM module has led to the electronically controlled eCALM (fig. 18). The pneumatic cabin suspension for driver's cab applications has considerably reduced energy consumption in the vehicle due to the new electronic control unit (fig. 19). This means that the entire air system (compressor, accumulator, drier) can be designed to be smaller and lighter in weight. There is the option of also having the compressor operated electrically by integrating it into the eCALM system which means it actuates based on need. In vehicles without a centralized compressed air system, eCALM and its integrated compressor can generate air suspension in the driver's cab.

Also, with eCALM, additional new features such as leveling, lowering and raising the cabin to different levels can be offered. Ergonomic driving with slope compensation offers additional benefits such as access to difficult-to-reach components in the service position.

Working together with its customers, ZF has raised the bar when it comes to effectively controlling cabin movements. eCALM combined with ZF’s semi-active CDC damper system provides the ideal basis for maximum drive comfort for the mobile workplace.

A positive driving experience in the vehicle is no luxury, but the precondition that the driver can work with his vehicle safely, relaxed and attentively. As a system supplier ZF develops and manufactures cabin suspensions for all vehicle applications – including springs, vibration dampers and rubber metal components. In this context the solution offered by ZF is optimally adapted to the specific requirement. The drivers are profiting from a comfortable working place especially with significantly reduced cabin movements.

- Customized designs meet all customer requirements

- ZF products increase driving safety and comfort

Top working conditions in the cabin are becoming increasingly important for the success of construction vehicles. With its spring/damper units and systems, ZF is offering the ideal solution for almost any application, covering the whole range from steel spring module and air spring module to Cabin Air Levelling Module CALM and eCALM with integrated levelling control.

The steel-spring module (fig. 17) is the standard solution for cabins in construction machines and special-purpose vehicles. The advantages of steel springs in cabin dampers include simple installation by vehicle manufacturers, compact dimensions, and operations that do not require pressurized air.

Air springs for higher demands

The air-spring module provides considerably greater comfort. It is especially suited for installation in vehicles that carry a wide range of different loads – including in the cabin itself. It compensates for different cabin furnishings and ensures very comfortable damping and suspension performance.

CALM: Cabin Air Levelling Module

A further development of the air-spring module is the Cabin Air Levelling Module (CALM), which ZF developed together with WABCO. This module contains an integrated ride-height control system for the cabin. Depending on cabin height, a valve regulates the pressure in the air spring. CALM offers all the advantages of air springs, and in addition, its integrated height-control valve reduces the dimensions and simplifies installation. This additionally increases the reliability of the ride-height control system and prevents a dirt-related failure of the control valve.

eCALM: electronically controlled height leveling

The ongoing further development of the successful CALM module has led to the electronically controlled eCALM (fig. 18). The pneumatic cabin suspension for driver's cab applications has considerably reduced energy consumption in the vehicle due to the new electronic control unit (fig. 19). This means that the entire air system (compressor, accumulator, drier) can be designed to be smaller and lighter in weight. There is the option of also having the compressor operated electrically by integrating it into the eCALM system which means it actuates based on need. In vehicles without a centralized compressed air system, eCALM and its integrated compressor can generate air suspension in the driver's cab.

Also, with eCALM, additional new features such as leveling, lowering and raising the cabin to different levels can be offered. Ergonomic driving with slope compensation offers additional benefits such as access to difficult-to-reach components in the service position.

Working together with its customers, ZF has raised the bar when it comes to effectively controlling cabin movements. eCALM combined with ZF’s semi-active CDC damper system provides the ideal basis for maximum drive comfort for the mobile workplace.

A positive driving experience in the vehicle is no luxury, but the precondition that the driver can work with his vehicle safely, relaxed and attentively. As a system supplier ZF develops and manufactures cabin suspensions for all vehicle applications – including springs, vibration dampers and rubber metal components. In this context the solution offered by ZF is optimally adapted to the specific requirement. The drivers are profiting from a comfortable working place especially with significantly reduced cabin movements.