Electrification – Zero emissions and maximum performance - ZF CMe – Benchmark for electric mixer drives in the market

- Technology leader ZF is setting new standards for electrical drives, especially when it comes to compact equipment

At this year´s BAUMA China ZF presents several ground-breaking innovations that pave the way for the construction site of the future. Guided by the principle of zero emissions, ZF strives to achieve the ambitious claim of enabling construction machinery to operate emission-free in the future.

ZF CMe – Benchmark for electric mixer drives in the market

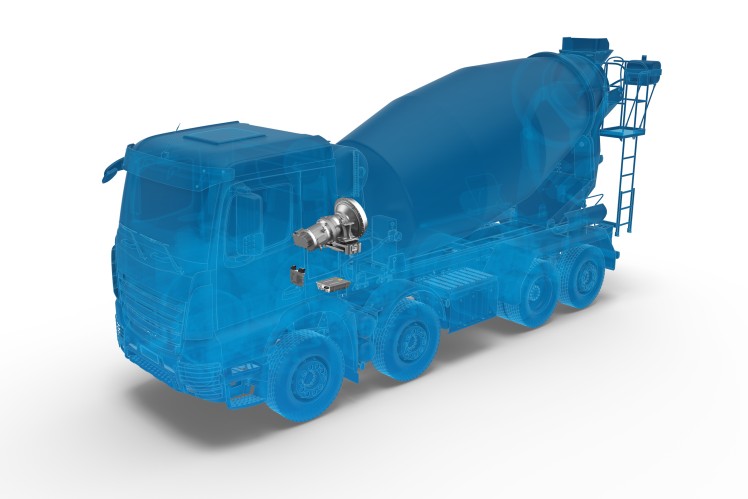

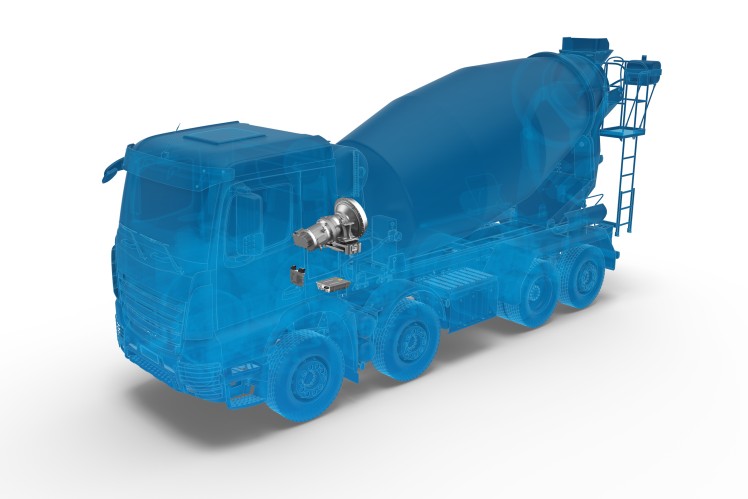

ZF offers an electric drum mixer drive teamed with a battery as an energy source for mixer trucks. This guarantees customers security when investing in and planning the procurement of new transit mixers. Traditional mixer drum drives operate via high pressure hydraulics that require the truck’s combustion engine to drive a PTO connected to the hydraulic pump. The new electro-mechanic transmission (CMe) concept is replacing all hydraulic components. The Transmission is now driven by an integrated powerful PMSM machine with up to 100kW.

The System can be powered by the HEVs (hybrid electric vehicle), BEVs (battery electric vehicle) or FCEVs (fuel-cell electric vehicle) with an on-board high-voltage (HV) Battery.

Even with a HEV system, the truck can turn off its engine on the construction site as well as in the mixing plant and let the drum run independently and emission-free, powered by the high-voltage (HV) battery.

The battery can be charged on the mixer system by cable and by a built-in generator when being driven (fig. 7).

Some of the benefits of this system for mixer trucks with electromechanical drum drive include compactness, low weight, and durability even for strenuous construction applications.

The system satisfies all the expectations for performance and productivity found in traditional mixer trucks and combines them with the extensive benefits and opportunities that electromechanical systems have to offer. (fig. 8).

- Up to 12 m3 mixing capacity

- Up to max. output torque 80,000 Nm

- Max. motor power 100 kW

- Emission-free operation on-site

- Less energy/fuel consumption

- Low noise

- Lower CO₂ emissions

The energy source for the drive system is a powerful battery. During operation, the vehicle can access 60 kW continuous power and a peak power of 100 kW for a shorter period.

The 650 V used by the high voltage system was specially selected for reduced power loss. Further, this is emerging as the standard in the electric commercial vehicles sector.

The electric drive technology from ZF makes the mixer truck an efficient vehicle, ready to meet future market demands.

Technology leader ZF is setting new standards for electrical drive trains in construction machinery.

In addition to the initially introduced electrical mixer drive, ZF is also working on electric drive train solutions for backhoe loaders, telehandlers, wheel loaders and wheeled excavators. The ZF eTRAC emission free driveline system based on different voltage levels, from 48 V to 600 V, offers the right performance for every application. ZF is acting as a system supplier and delivers the electric drive unit, in combination with front and rear axles, power electronics and Control Unit (fig. 9). These best in class solutions achieve the same output as conventional drivetrains, without compromising on performance factors such as traction and top speed. The first product of the eTRAC range has been successfully launched in compact wheel loaders in the European market.

- ZF CMe – Benchmark for electric mixer drives in the market

- Technology leader ZF is setting new standards for electrical drives, especially when it comes to compact equipment

At this year´s BAUMA China ZF presents several ground-breaking innovations that pave the way for the construction site of the future. Guided by the principle of zero emissions, ZF strives to achieve the ambitious claim of enabling construction machinery to operate emission-free in the future.

ZF CMe – Benchmark for electric mixer drives in the market

ZF offers an electric drum mixer drive teamed with a battery as an energy source for mixer trucks. This guarantees customers security when investing in and planning the procurement of new transit mixers. Traditional mixer drum drives operate via high pressure hydraulics that require the truck’s combustion engine to drive a PTO connected to the hydraulic pump. The new electro-mechanic transmission (CMe) concept is replacing all hydraulic components. The Transmission is now driven by an integrated powerful PMSM machine with up to 100kW.

The System can be powered by the HEVs (hybrid electric vehicle), BEVs (battery electric vehicle) or FCEVs (fuel-cell electric vehicle) with an on-board high-voltage (HV) Battery.

Even with a HEV system, the truck can turn off its engine on the construction site as well as in the mixing plant and let the drum run independently and emission-free, powered by the high-voltage (HV) battery.

The battery can be charged on the mixer system by cable and by a built-in generator when being driven (fig. 7).

Some of the benefits of this system for mixer trucks with electromechanical drum drive include compactness, low weight, and durability even for strenuous construction applications.

The system satisfies all the expectations for performance and productivity found in traditional mixer trucks and combines them with the extensive benefits and opportunities that electromechanical systems have to offer. (fig. 8).

- Up to 12 m3 mixing capacity

- Up to max. output torque 80,000 Nm

- Max. motor power 100 kW

- Emission-free operation on-site

- Less energy/fuel consumption

- Low noise

- Lower CO₂ emissions

The energy source for the drive system is a powerful battery. During operation, the vehicle can access 60 kW continuous power and a peak power of 100 kW for a shorter period.

The 650 V used by the high voltage system was specially selected for reduced power loss. Further, this is emerging as the standard in the electric commercial vehicles sector.

The electric drive technology from ZF makes the mixer truck an efficient vehicle, ready to meet future market demands.

Technology leader ZF is setting new standards for electrical drive trains in construction machinery.

In addition to the initially introduced electrical mixer drive, ZF is also working on electric drive train solutions for backhoe loaders, telehandlers, wheel loaders and wheeled excavators. The ZF eTRAC emission free driveline system based on different voltage levels, from 48 V to 600 V, offers the right performance for every application. ZF is acting as a system supplier and delivers the electric drive unit, in combination with front and rear axles, power electronics and Control Unit (fig. 9). These best in class solutions achieve the same output as conventional drivetrains, without compromising on performance factors such as traction and top speed. The first product of the eTRAC range has been successfully launched in compact wheel loaders in the European market.

MEDIA

CONTACT