ZF is Electrification Zero Emission – System Optimization boosted by Electrification

- ZF Generator Module TERRA+

- Electric Drives for Implements

- Electric Drives for Compact Vehicles

ZF Generator Module TERRA+

With the integrated generator module ZF TERRA+, ZF presents a solution for high and low-voltage systems for continuously variable tractor transmissions of the TERRAMATIC series. The generator module is integrated in the housing of the transaxle. Mechanical power supplied by the engine is converted into electric power and can be used directly for the implement or the tractor.

Through the generation and use of electric power a higher diesel engine performance can be allowed as it is not transferred to the mechanical transmission drivetrain but directly converted into electric power.

A relatively large combustion engine, for example, can thus be combined with a smaller transmission (transmission downsizing). By using the available electric power it is also possible for a lighter tractor to operate larger implements in combination with an electric traction drive.

TERRA+ High voltage version:

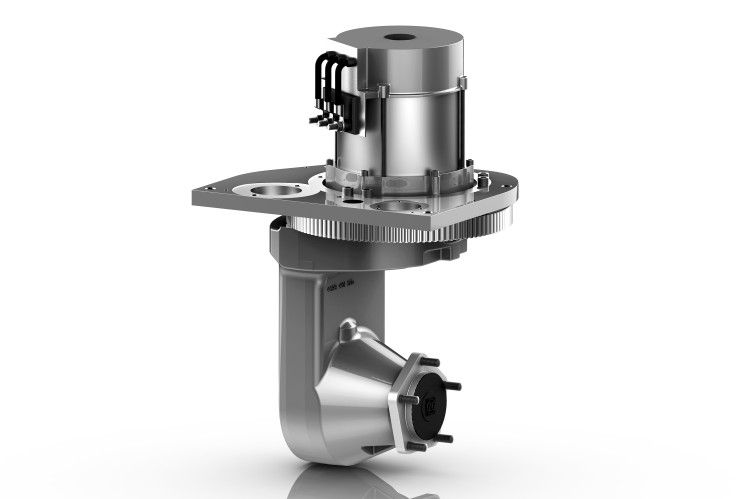

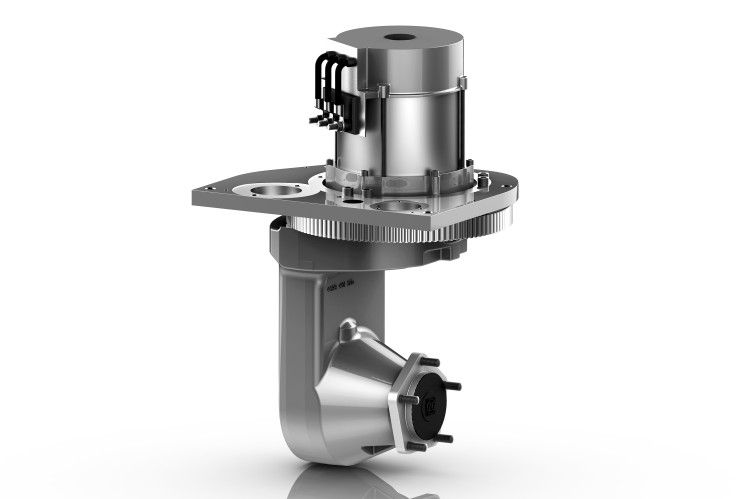

The high-voltage generator and inverters serve as a tractor power source, delivering up to 80 kW of continuous electric power.

Furthermore an extension to a hybrid system is possible. (fig 7)

TERRA+ Low voltage version:

For applications with a continuous electric power requirement up to

approximately 20 kW are electric motors and inverters to 48 V low-voltage transmissions suitable as used in passenger car hybrid transmissions. (fig 8)

Electric drives for implements and trailers

With single wheel drive and central drive concepts (fig 9) ZF shows how electromechanical systems can also be applied in Off-Highway applications. The electrification of the driveline with electrified PTO as well as the electric single wheel drive of the ZF eTRAC series (fig 10) ensure ideal forward driving in the field, as well for the trailer as for the implement (Traction Management).

The scope of deployment for this innovations is wide ranging. Electric driven axle systems for trailers as well as electric driven stabilizer wheels for various implements are just some examples to be mentioned. Thanks to controlled traction support on implements and due to the higher system performance, the power of impact of the tractor-trailer unit is increased and working under difficult conditions is made easier (fig 11).

With nowadays vehicle sizes, there are more and more technical, physical and agricultural limits.

The transmission of power between tires and ground, associated slip limits as well as dynamic and static ground stress (soil compression and rolling frequency) are particularly in focus here.

The electric traction drive requires a lower tractive effort by the tractor. Therefore either more powerful implements can be operated, or a smaller tractor can be used. This increases productivity and reduces fuel consumption and soil compaction. (film 12).

In combination with appropriate traction management, systems with electric traction drives on implements offer significant advantages when it comes to usage on loose ground. System optimization with electrically distributed traction management has the potential to boost both productivity and tractive effort. To encourage the breakthrough

in terms of the performance required from electric traction drives on implements, a modular drive system was developed with the best possible potential for synergies with other applications.

Electric Drive Systems for Compact Vehicles

Electric drive systems for solely electric driven compact vehicles e.g. yard tractors – whether batteries or fuel cells serving as an energy storer - have a whole raft of advantages compared to diesel-powered vehicles, especially when it comes to agricultural engineering and municipal sector (fig 13). Driving with zero-emission and a considerably reduced noise level rank among the major advantages.

One of the key drivers is full zero-emission operation. This is part of ZF’s “Vision Zero” strategy for pollution-free vehicle systems.

ZF uses the following drive topologies to provide synergies between these electric drive systems and other applications:

- Axles with transfer case and central drive eTDA30

- Electric single wheel and steering drives for subcompact vehicles eTDW10 / GK Series

ZF eTRAC low voltage solutions (fig 14 and 15) allow synergies with established electric drive solutions from the Off-Highway sector. Together with the electric steering drive ZF eTRAC of the GK-series (fig16), they represent an ideal technical driving solution for subcompact vehicles, self-propelled vehicles or field robots.

Zero Emission – System Optimization boosted by Electrification

- ZF Generator Module TERRA+

- Electric Drives for Implements

- Electric Drives for Compact Vehicles

ZF Generator Module TERRA+

With the integrated generator module ZF TERRA+, ZF presents a solution for high and low-voltage systems for continuously variable tractor transmissions of the TERRAMATIC series. The generator module is integrated in the housing of the transaxle. Mechanical power supplied by the engine is converted into electric power and can be used directly for the implement or the tractor.

Through the generation and use of electric power a higher diesel engine performance can be allowed as it is not transferred to the mechanical transmission drivetrain but directly converted into electric power.

A relatively large combustion engine, for example, can thus be combined with a smaller transmission (transmission downsizing). By using the available electric power it is also possible for a lighter tractor to operate larger implements in combination with an electric traction drive.

TERRA+ High voltage version:

The high-voltage generator and inverters serve as a tractor power source, delivering up to 80 kW of continuous electric power.

Furthermore an extension to a hybrid system is possible. (fig 7)

TERRA+ Low voltage version:

For applications with a continuous electric power requirement up to

approximately 20 kW are electric motors and inverters to 48 V low-voltage transmissions suitable as used in passenger car hybrid transmissions. (fig 8)

Electric drives for implements and trailers

With single wheel drive and central drive concepts (fig 9) ZF shows how electromechanical systems can also be applied in Off-Highway applications. The electrification of the driveline with electrified PTO as well as the electric single wheel drive of the ZF eTRAC series (fig 10) ensure ideal forward driving in the field, as well for the trailer as for the implement (Traction Management).

The scope of deployment for this innovations is wide ranging. Electric driven axle systems for trailers as well as electric driven stabilizer wheels for various implements are just some examples to be mentioned. Thanks to controlled traction support on implements and due to the higher system performance, the power of impact of the tractor-trailer unit is increased and working under difficult conditions is made easier (fig 11).

With nowadays vehicle sizes, there are more and more technical, physical and agricultural limits.

The transmission of power between tires and ground, associated slip limits as well as dynamic and static ground stress (soil compression and rolling frequency) are particularly in focus here.

The electric traction drive requires a lower tractive effort by the tractor. Therefore either more powerful implements can be operated, or a smaller tractor can be used. This increases productivity and reduces fuel consumption and soil compaction. (film 12).

In combination with appropriate traction management, systems with electric traction drives on implements offer significant advantages when it comes to usage on loose ground. System optimization with electrically distributed traction management has the potential to boost both productivity and tractive effort. To encourage the breakthrough

in terms of the performance required from electric traction drives on implements, a modular drive system was developed with the best possible potential for synergies with other applications.

Electric Drive Systems for Compact Vehicles

Electric drive systems for solely electric driven compact vehicles e.g. yard tractors – whether batteries or fuel cells serving as an energy storer - have a whole raft of advantages compared to diesel-powered vehicles, especially when it comes to agricultural engineering and municipal sector (fig 13). Driving with zero-emission and a considerably reduced noise level rank among the major advantages.

One of the key drivers is full zero-emission operation. This is part of ZF’s “Vision Zero” strategy for pollution-free vehicle systems.

ZF uses the following drive topologies to provide synergies between these electric drive systems and other applications:

- Axles with transfer case and central drive eTDA30

- Electric single wheel and steering drives for subcompact vehicles eTDW10 / GK Series

ZF eTRAC low voltage solutions (fig 14 and 15) allow synergies with established electric drive solutions from the Off-Highway sector. Together with the electric steering drive ZF eTRAC of the GK-series (fig16), they represent an ideal technical driving solution for subcompact vehicles, self-propelled vehicles or field robots.

MEDIA

CONTACT